Description

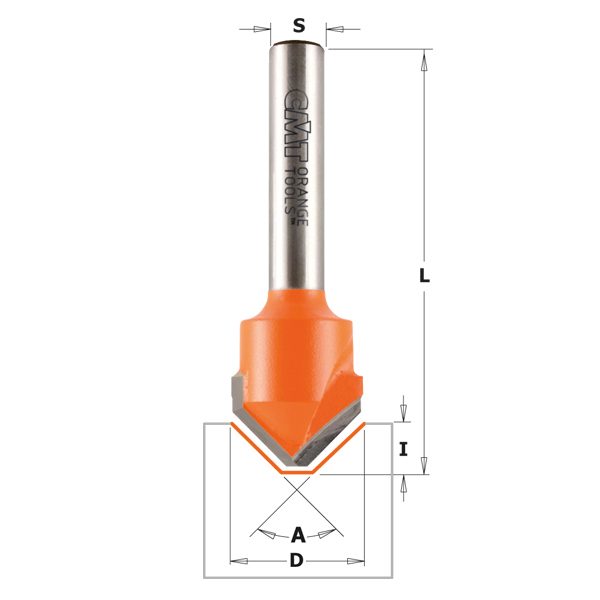

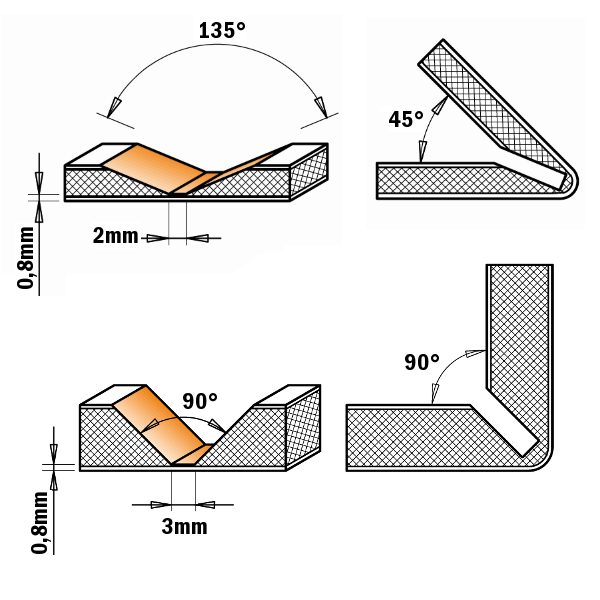

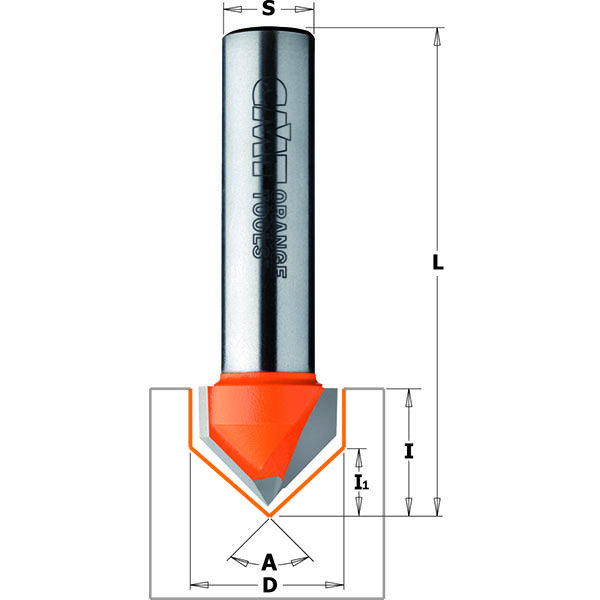

ALUCOBOND? plus composite panels can be shaped using a very simple processing method. The technique, called the routing and folding method, enables a fabricator to produce shapes of various kinds and sizes. A V-shaped groove is routed on the reverse side of the ALUCOBOND? plus composite panel using a ?V? groove router bit. A thin layer of the core material should be left at the base of the groove, i.e. on the inside of the outer cover sheet. The untouched outer cover sheet can now be bent manually, giving an exact and clean folding line which follows the routed groove. The outer radius of the folded edge depends on the shape of the groove and its depth. We recommend that the routing be done using a CNC machining center, a portable sheet milling machine or a hand router. The routing and folding method can be used for ALUCOBOND? plus composite panels with all available standard surface finishes.

The advantages of this unique technique are:

-Low investment cost.

-Simple fabrication technique.

-Folding can be done on site, saving transportation cost.

-Low-cost fabrication of shaped components, wall cladding, roof edgings, column cladding, flashings, etc.

-Flexibility in creating shapes.

-Very economical.

-Shapes are not limited by machine capacity.